Polysilsesquioxane

What is PSQ?

Polysilsesquioxane (PSQ) composed of siloxane bonds (Si-O-Si) synthesized from trifunctional organosilane compounds. PSQ is an organic-inorganic hybrid material, which has inorganic features (i.e. excellent transparence, heat resistance, weather resistance, and hardness) and organic functional groups, so PSQ shows different properties from silicone oil, silicone rubber and silica.

Introduction of Konishi chemical’s PSQ

We provide PSQ with the following lineup

- SR series

-

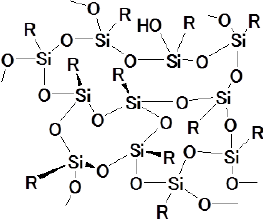

PSQ oligomer and polymer mainly composed of random structure.

Features of SR series

SR series is PSQ oligomer and polymer mainly composed of random structure. Reactive end groups remained in SR series; therefore siloxane bond crosslinks are formed by heating and obtained cured products with excellent durability.

Introduction of SR series

SR series have organic functional groups of methyl and/or phenyl group.

Product Lineup of SR series

| Product | Functional Group R | End Group | Mw | Stage | |

|---|---|---|---|---|---|

| SR | |||||

| -23 | Phenyl | -Si-OH -Si-OEt |

1,000~5,000 | Lab | |

| -13H | Methyl | -Si-OH -Si-OEt |

3,000~10,000 | Pilot | |

| -3321 | Methyl/Phenyl | -Si-OH -Si-OEt |

1,000~10,000 | Lab | |

(Not quality standards)

An usage example of SR series

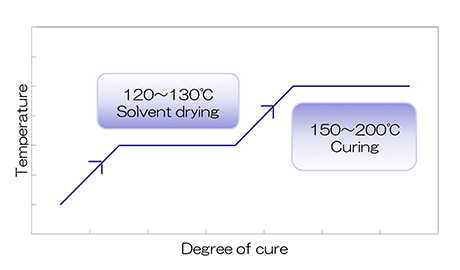

An example of preparation of curing PSQ resin is shown below.

[Conditions]

PSQ type:SR-13(R = Methyl)

Solvent:butyl acetate

Concentration:70wt%

1. PSQ varnish is Coated/Casted to substrate.

2. Solvent drying by heating to 120-130℃.

3. Cross-linking formation by heating to 150-200℃.

Image of temperature and curing progress

Image of temperature and curing progress

Physical Properties for PSQ

Curing resins of SR series show excellent heat resistance at high temperatures and light resistance in irradiation environments since they are composed of siloxane bonds that are more stable than C-C bonds. Furthermore, the resins can be used for various applications such as optical materials and insulating coating materials since they show high transparency, high hardness, low refractive index, and low dielectric constant.

Physical Properties of SR-13

| Test | Method | Value |

|---|---|---|

| Specific weight[g/cm3] | Gravimeter | 1.25~1.27 |

| Surface hardness | Pencil hardness thickness:0.5mm | 6H |

| Transmittance | wavelength:400nm thickness:0.5mm | 93% |

| Refractive index | Spectroscopic interferometry wavelength:589nm(sodium D lines) | 1.42 |

| Td5 | TG-DTA | 409℃ |

| Tg | DSC | ≧409℃ |

| Thermal conductivity[W/m・K] | Laser flash method | 0.31 |

| Coefficient of thermal expansion[×10-4 K-1] | TMA | 1.8~2.4 |

| Dielectric constant(1GHz) | Impedance Analysis | 3.2 |

| Dielectric loss tangent(1GHz) | Impedance Analysis | 0.0009 |

(Not quality standards)

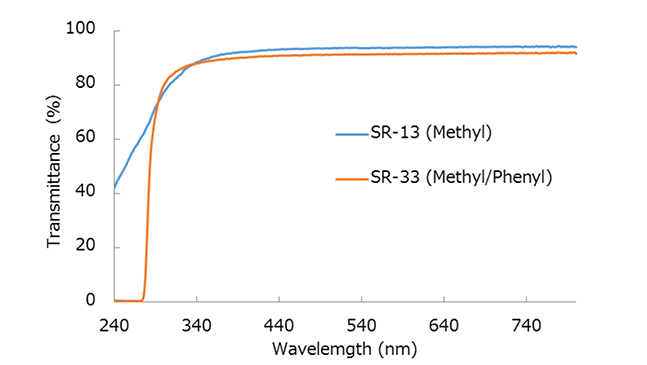

Transmittance Spectra of SR serise

High transmittance in visible light region.

High transmittance in visible light region.

[Conditions] Sample thickness : 0.5mm

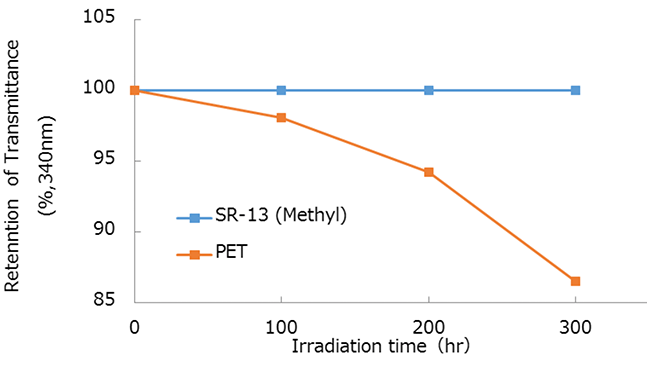

Fade Meter Test of SR-13

High durability in prolonged light irradiation.

High durability in prolonged light irradiation.

[Conditions] Sample thickness : 0.5mm

Amounts of UV irradiation : 0.15 MJ/m2・hr