Functional Sulfonated Polymer

What is Functional Sulfonated Polymer?

Functions of sulfonated group contain proton conductivity, electron conductivity and hydrophilicity, etc. In recent years, sulfonated polymer materials such as ion exchange materials, separator for battery, and separation membrane are attracting attention.

Sulfonated Polyether sulfone【S-PES】

We hereby introduce Functional Sulfonated Polymer which is Sulfonated Polyether sulfone(S-PES)

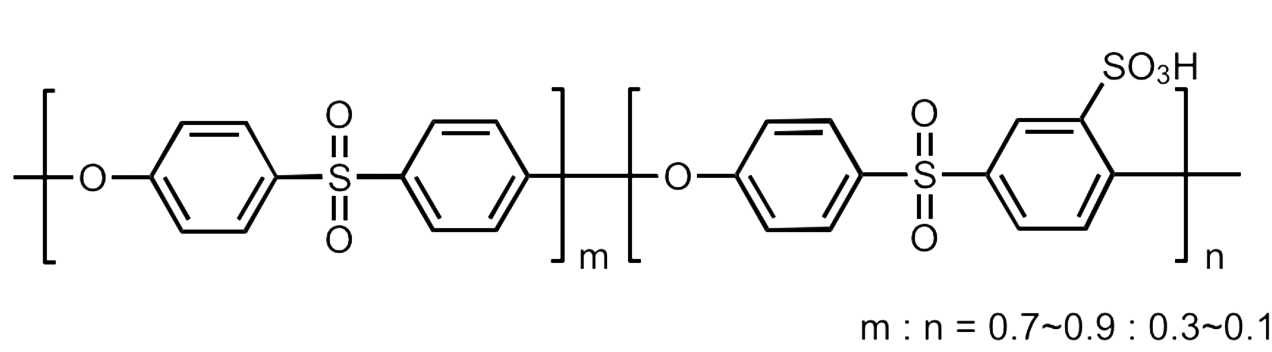

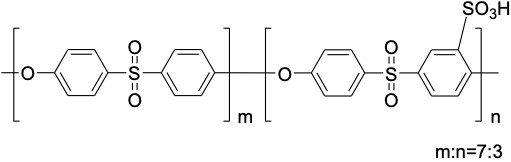

■Typical structural formula of Sulfonated Polyether sulfone(S-PES)

■An example of S-PES quality

| Items | An example of S-PES quality |

|---|---|

| Appearance | Light brown powder |

| Sulfonation degree | 30% |

| Water contents | ≤ 3% |

| Weight-average molecular weight | 130,000 |

| Developmental stage | Pilot stage |

Novel Sulfonation Technology

Sulfonation of polymers in the conventional technology had the problem that the molecular weight declined as the reaction progressed. We developed a new sulfonation method for aromatic polymers and succeeded in achieving both high sulfonation degree and prevention of molecular weight reduction. (Konishi Chemical Ind. Co., Ltd. Patent No. JP5824734, US9228060, KR10-1731242, CN103998492, DE112012005418, TW522394)

■New manufacturing method of S-PES

| New method | Conventional-1 | Conventional-2 | Raw material PES | Target | |

|---|---|---|---|---|---|

| Sulfonation degree | 30% | 9% | 30% | - | 30% |

| Weight-average molecular weight | 130,000 | 100,000 | 20,000 | 100,000 | 100,000~150,000 |

The following are examples of application of S-PES to water treatment membrane and ion exchange membrane for redox flow battery.

Application to water treatment membrane

S-PES/PES blend hollow fiber membrane module improved fouling resistance compared to PES membrane.

What is fouling?

The hydrophobic surface adsorbs organic compounds etc. due to the interaction.

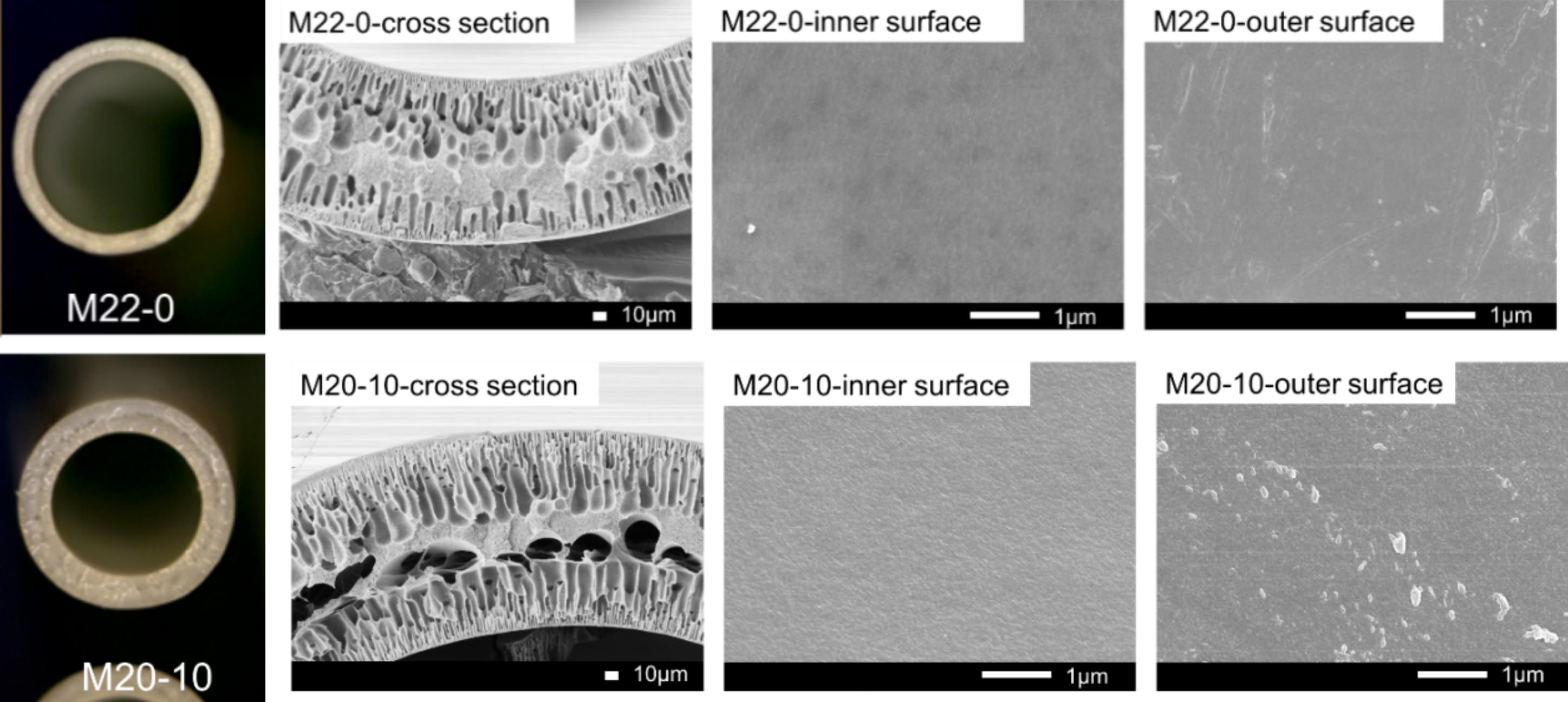

■S-PES/PES blend hollow fiber membrane

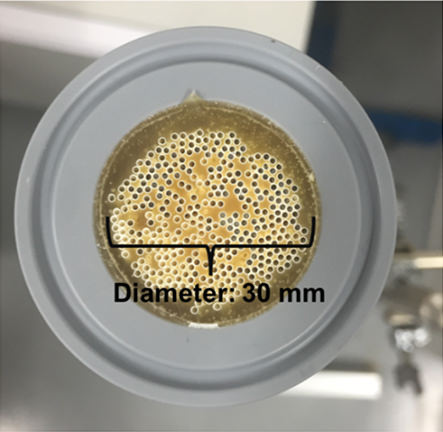

Figure:The morphology of pure PES(M22-0) and S-PES/PES (M20-10:S-PES/PES ratio:1/9) blend hollow fiber membranes

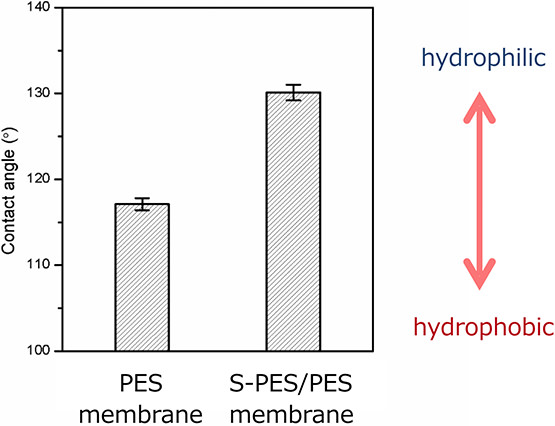

■Air bubble contact angle

The surface hydrophilicity of the PES and S-PES/PES blend membranes were characterized by the air bubble contact angle. We measured contact angle between membrane and air in water.

The results indicated that the S-PES/PES blend membranes was more hydrophilic than the PES membrane.

Figure: Air bubble contact angle of PES and S-PES/PES blend membrane(S-PES/PES ratio:1/9)

Figure: Air bubble contact angle of PES and S-PES/PES blend membrane(S-PES/PES ratio:1/9)

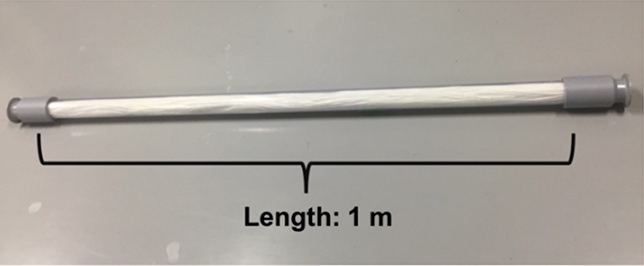

■S-PES/PES blend hollow fiber membrane module

The drying bundle of the hollow fiber membranes(M22-0, M20-10) was placed into a module with a length of 1 m and ~ 330 pieces of fibers. The module was designed to be an “out to in” filtration type and hollow fibers only opened at one end.

The photo of full size membrane module with the length of 1 m.

The photo of full size membrane module with the length of 1 m.

The outlet for the permeate solution of a membrane module.

The outlet for the permeate solution of a membrane module.

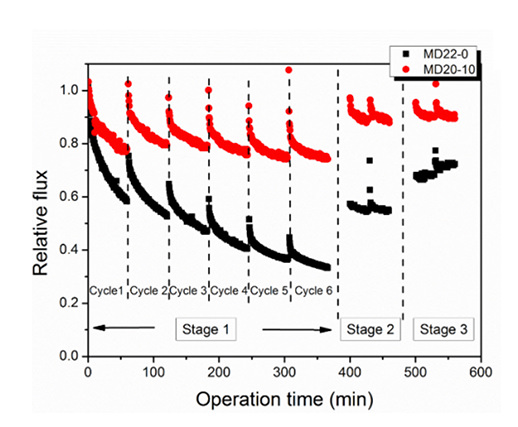

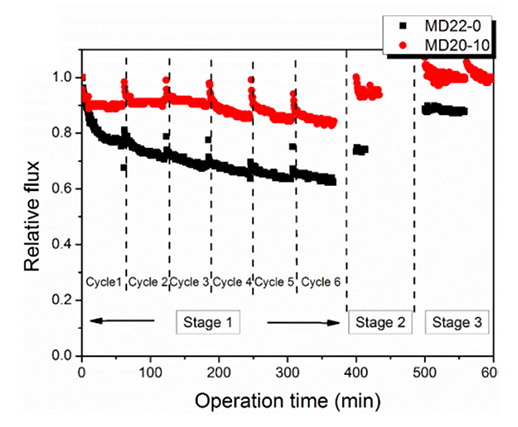

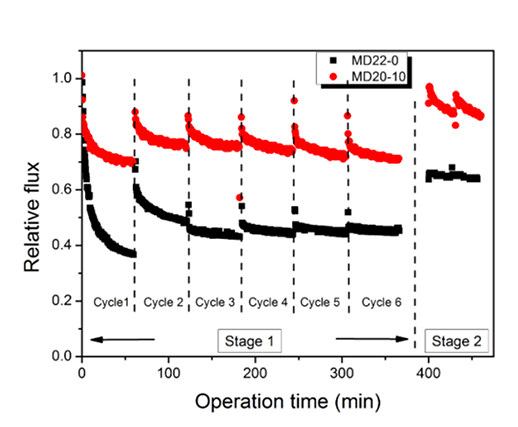

■Antifouling Properties of Membrane Modules

Typical model foulants (sodium alginate(SA), sodium humate(HA) and bovine serum albumin (BSA)) were used to evaluate the membrane antifouling properties. The flux decay during fouling process for S-PES/PES blend hollow fiber membranes module was obviously suppressed when compared with that for PES hollow fiber membranes module.

SA 100 ppm

HA 100 ppm

BSA 100 ppm

■(MD22-0):PES

●(MD20-10):S-PES/PES membrane module

Figure: Effect of different model foulants (SA, HA and BSA) on the antifouling properties of full-size membrane modules.

【引用】

H. Matsuyama et al., Ind. Eng. Chem. Res., 2017, 56, 11302–11311

H. Matsuyama et al., Ind. Eng. Chem. Res., 2018, 57, 4430−4441

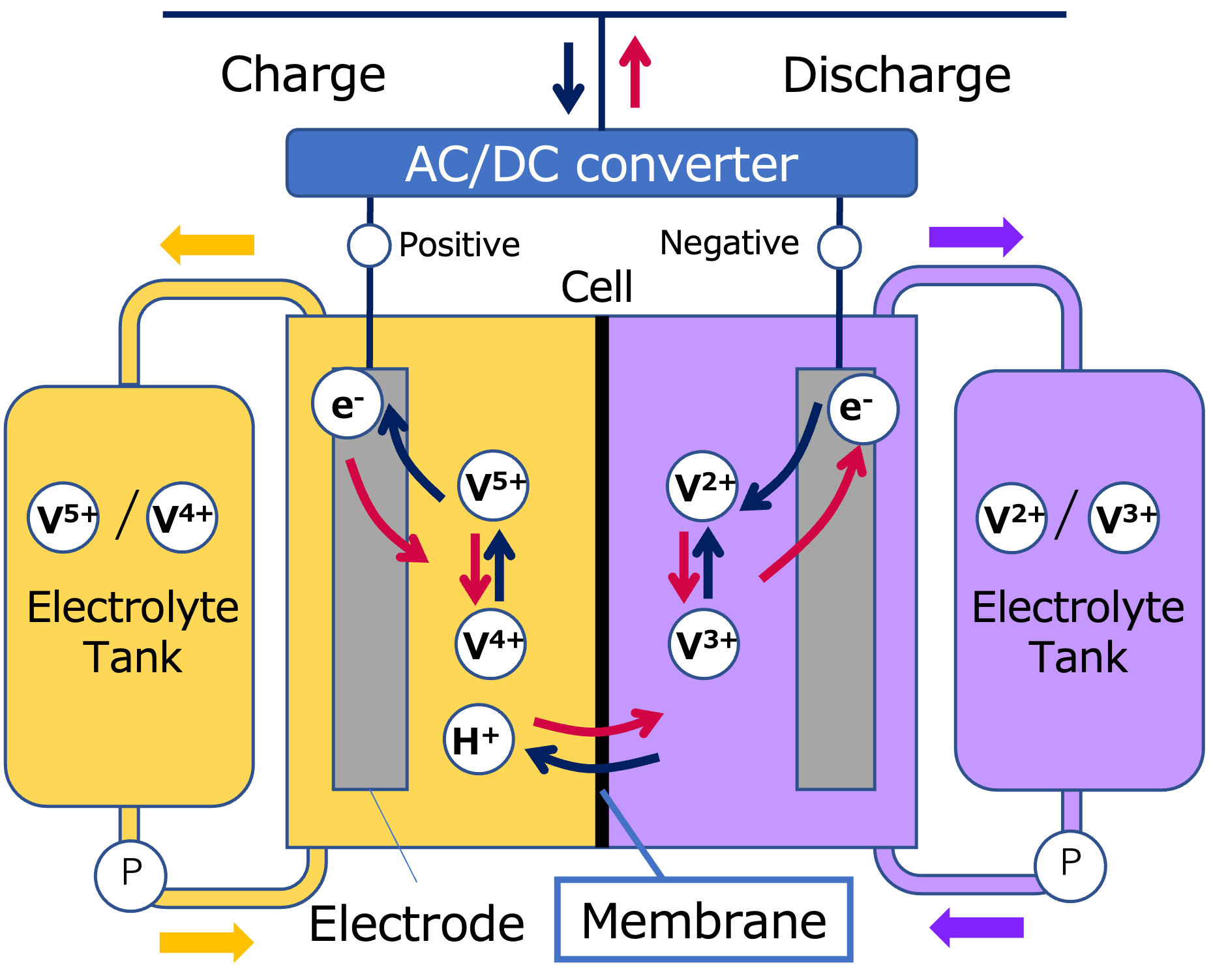

Application to ion exchange membrane for redox flow battery

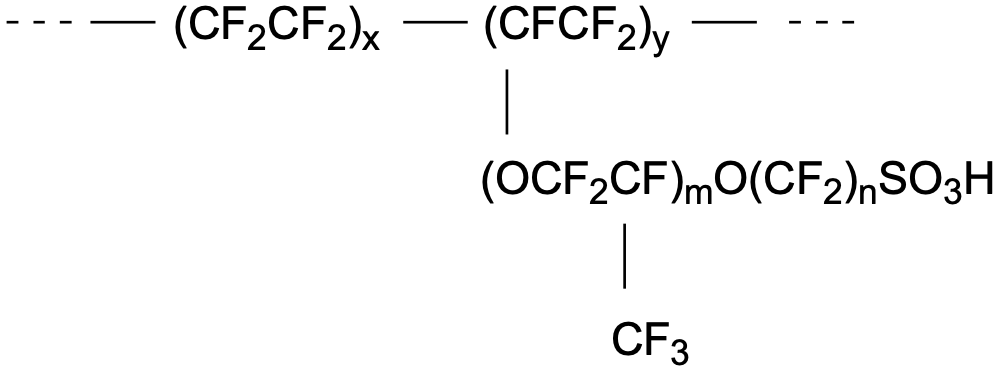

Vanadium redox flow batteries have excellent charge/discharge cycle resistance and safety, so they are expected to be used as large-scale secondary batteries for renewable energy applications. The electrolyte membrane material currently in use is perfluorocarbon sulfonic acid polymer, but it is thought that the extremely high cost and high environmental impact are hindering its widespread practical use.

For this reason, there is a need for electrolyte membranes using hydrocarbon materials.

■Preparation of membrane and performance evaluation

We prepared a S-PES membrane and evaluated its performance as an electrolyte membrane for redox flow batteries.

S-PES powder

S-PES powder

S-PES membrane

S-PES membrane

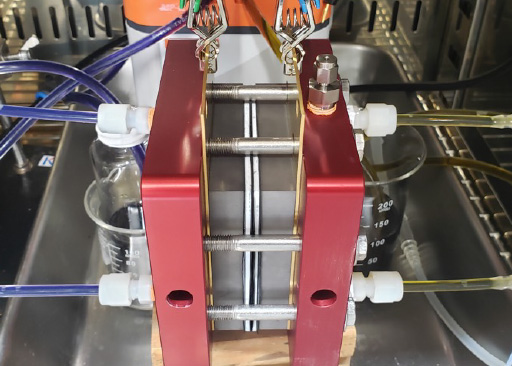

Electrolyte membrane evaluation device Small cell with electrode area of 25cm2

Electrolyte membrane evaluation device Small cell with electrode area of 25cm2

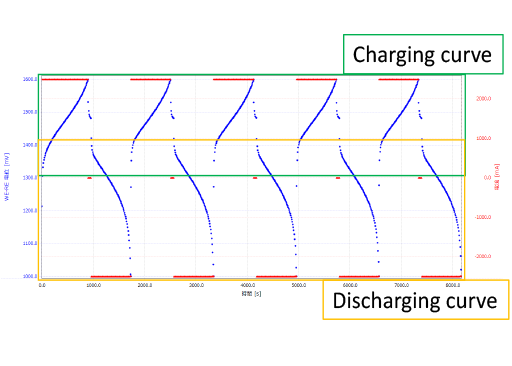

Charge/discharge cycle test plot of S-PES membrane plotted regularly ⇒ Stable charging/discharging is possible

Charge/discharge cycle test plot of S-PES membrane plotted regularly ⇒ Stable charging/discharging is possible

■Performance of S-PES membrane

This research was selected for the NEDO in 2020.

As a result of performance evaluation, good results were obtained in the membrane resistance test and crossover test (proton selectivity).

| Perfluorocarbon sulfonic acid membrane |

S-PES membrane | |

|---|---|---|

| Structural formula |

|

|

| Membrane resistance※1 (Perfluorocarbon sulfonic acid film is set to 1.0) |

1.0 | 0.7 |

| Permeability coefficient for vanadium※2 (Perfluorocarbon sulfonic acid film is set to 1.0) |

1.0 | 0.03 |

※1: It represents the difficulty of hydrogen ion movement, and the smaller the value, the better the performance. ※2:This is an indicator of how easily vanadium moves between the positive and negative electrodes. When vanadium moves between the positive and negative electrodes, self-discharge occurs and battery performance deteriorates. Therefore, the smaller the permeability coefficient of vanadium, the better the performance.

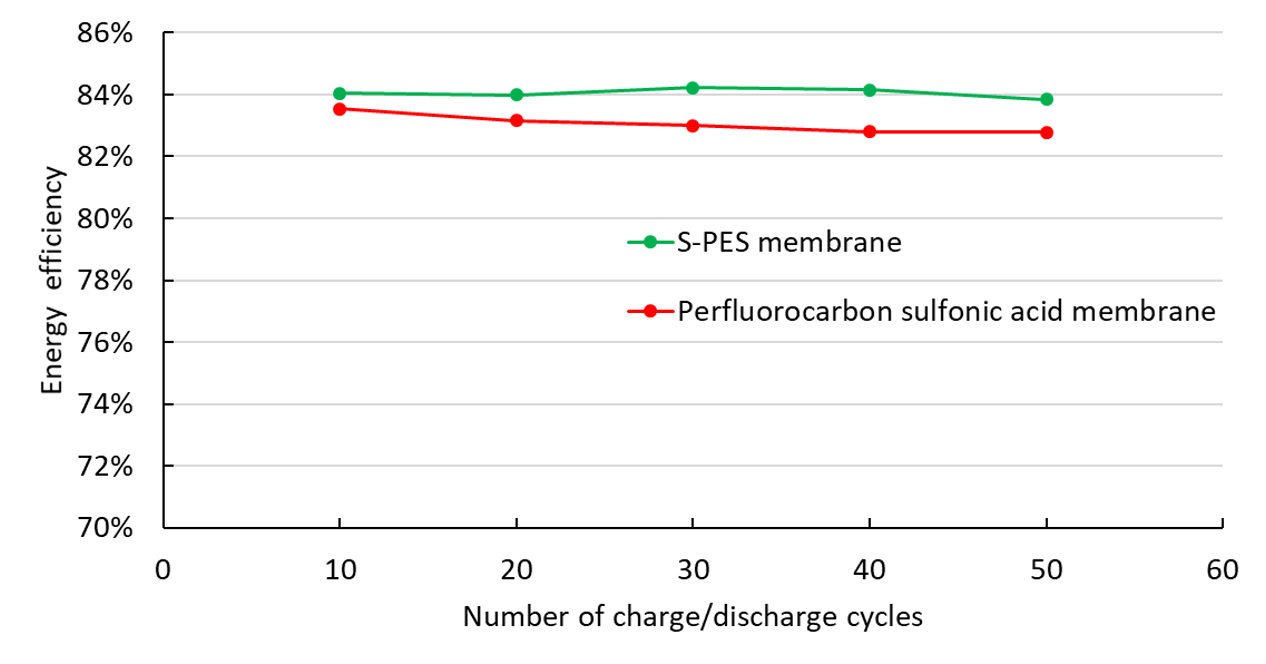

We have developed an S-PES membrane that has energy efficiency ※3 equal to or higher than that of perfluorocarbon sulfonic acid membranes.

※3:Flow 3M sulfuric acid containing 1M V3+ into the negative electrode liquid and 3M sulfuric acid containing 1M V4+ into the positive electrode liquid, and charge and discharge 50 times.

This result was obtained as a result of the NEDO lead research program "Research and development of a new type of redox flow battery as a vanadium substitute (JPNP14004)".